The CVP2000 series intelligent valve positioner is a new generation high-performance intelligent valve positioner equipped with a microprocessor. The intelligent positioner receives DC current signals from the control device and controls the pneumatic control valve. In addition to this basic function, CVP2000 also has communication function, automatic configuration program, and self diagnostic function, which will greatly improve productivity and factory operation efficiency. These advanced features can also be achieved through communication devices such as HART, APL, FF, etc. The CVP2000 series can be stably used for linear or angular stroke control valves with single acting (spring reset) pneumatic actuators or double acting pneumatic actuators.

Product Description

· CVP2000-1 model: Ex ia Ⅱ C T4...T6 Ga

· CVP2000-2 model: Ex db Ⅱ C T4...T6 Gb; Ex ia Ⅱ C T4...T6 Ga; Ex tb Ⅱ C T80℃...T130℃ Db

· CVP2000-3 model: Ex db Ⅱ C T4...T6 Gb; Ex ia Ⅱ C T4...T6 Ga; Ex tb Ⅱ C T80℃...T130℃ Db.

· Explosion-proof with flameproof, intrinsic safety, and dust protection, ensuring safety and reliability.

· Modular design for easy use and maintenance.

· High precision and fast response speed.

· OLED display allows operation in lower temperatures.

· Supports two-wire system: (4~20)mA signal, APL signal, FF signal, etc.

· Parameters can be set locally or remotely.

· Low power consumption, low air consumption, and low operating co

· Simple and clear user interface, with both Chinese and English language options, 180° screen rotation for easier use.

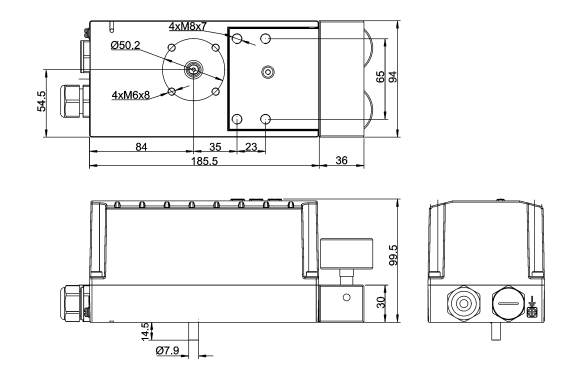

CVP2000-1/0

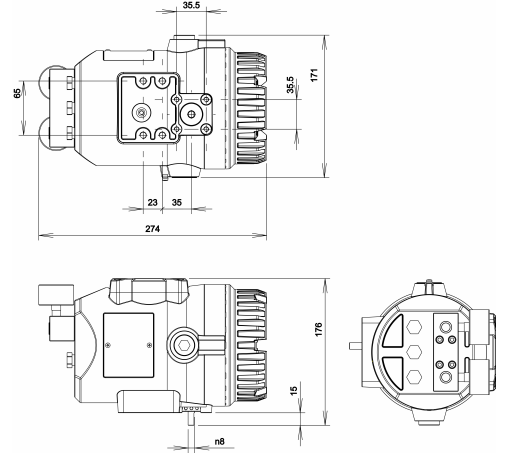

CVP2000-2

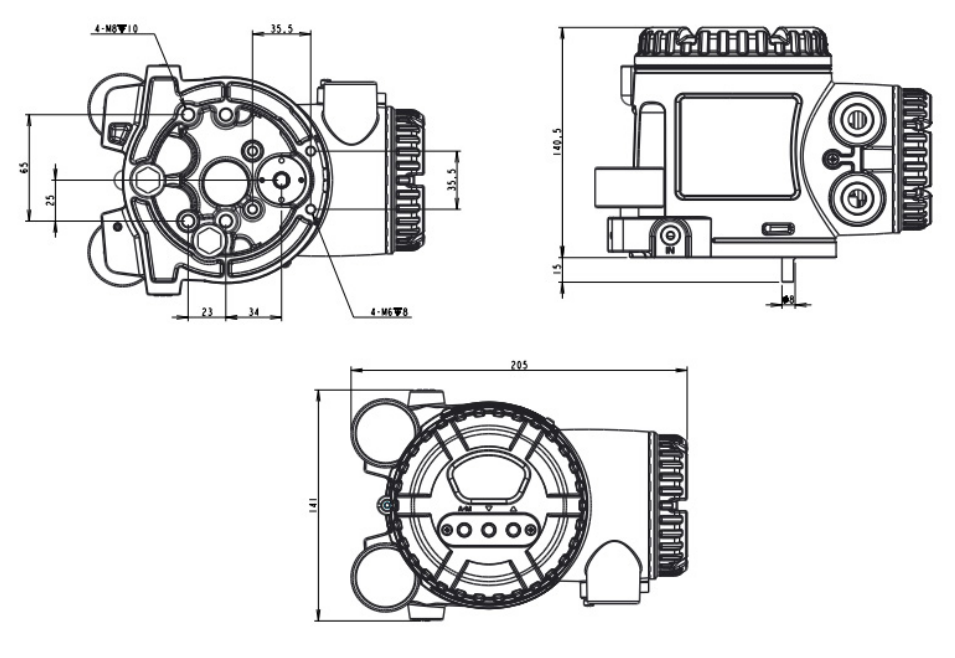

CVP2000-3

TECHNICAL PARAMETERS

| Table 1: Basic Parameters | ||

| Position range | Linear actuator:10mm~130mm | |

| Rotary actuator:30°~100° | ||

| Compressed Air pressure | (0.14~0.7)MPa | |

| Compressed Air requirement | Conforms to ISO 8573-1;oil content conforms to Class Ⅲ | |

| solid particle size and density conforms to Class Ill; the dew point temperature is 10℃ below the minimum operating temperature | ||

| Steady state air consumption | 0.024 Nm³/h | |

| Rated inlet flow rate | 0.5MPa≥7.8Nm3/h | |

| Rated exhaust flow rate | 0.5MPa≥14.4Nm3/h | |

| Deadband | 0.1%~10% | |

| Accuracy | ±0.5% | |

| Hysteresis | ≤0.5% | |

| Display mode | OLED,0/180°optional | |

| Table 2:(4~20)mA Signal Input | ||

| Power supply current | ≥3.5mA | |

| Rated signal range | (4~20)mA | |

| Load voltage(20mA) | ≤8VDC (non-HART);≤10.5VDC(HART) | |

| Impedance (20mA) | ≤4000(non-HART);≤5250(HART) | |

| Communication method | HART communication (optional) | |

| Table 3:APL signal input | |

| Working voltage range | (9~15)V |

| Input current | (36~60)mA |

| Maximum Input Power | 0.54W |

| Bus signal input | 1V(peak-to-peak amplitude) |

| Communication method | APL |

| Table 4:FF signal input | |

| Working voltage range | (9~32)V |

| Communication method | FF |

| Table 5:Other Parameters | |

| Performance indicators | |

| Electromagnetic compatibility/EMC | Comply with IEC61000(GB/T 17626) |

| Rated insulation voltage | 1000VAC |

| Protection class | IP66 |

| Temperature effect | ≤0.015%/℃ |

| Dimensional indicators | |

| CVP2000-1/0 Type | 186mm*94mm*100mm (excluding pressure gauge module) |

| 222mm*94mm*100mm (including pressure gauge module) | |

| CVP2000-2 Type | 274mm*171mm*176mm |

| CVP2000-3.Type | 205mm*141mm*155.5mm |

| Weight | |

| CVP2000-1/0 Type | 2.1 Kg |

| CVP2000-2 Type | 5.6 Kg |

| CVP2000-3 Type | 2.9 Kg |

| Ingredients/Materials | |

| Housings. | CVP2000-1/0:ADC12 |

| CVP2000-2:ADC12 | |

| CVP2000-3:ADC12 | |

| Pressure gauge base | Aluminum AL6061 |

| Pressure gauge | Nickel-plated housing with copper connections;all stainless steel (optional) |

| Electrical connection | |

| Cable glands | 1/2 NPT or M20X1.5 |

| Pneumatic connection | RC1/4 or 1/4 NPT |

| Pressure gauge connection | RC1/8 |

| Compressed Air requirement | Conforms to ISO 8573-1;oil content conforms to Class Il;solid particle size and density conforms to Class I;the dew point temperature is 10℃ below the minimum operating temperature | |||

| Operating temperature | Non-hazardous environment: | |||

| CVP2000-0:-40℃~80℃ | ||||

| CVP2000-1:-40℃~80℃ | ||||

| CVP2000-2:-40℃~80℃ | ||||

| CVP2000-3:-40℃~80℃ | ||||

| Explosive gas environment. | ||||

| Explosion proof mark:Ex db ⅡCT4..T6 Gb,Ex tb ⅢCT80℃..T130℃ Db | ||||

| Temperaturegroup(gas) | Maximum surface temperature(dust) | Operating ambient temperature Ta | ||

| T4 | T130℃ | -40℃+80℃ | ||

| T5 | T95℃ | -40℃+65℃ | ||

| T6 | T80℃ | -40℃+50℃ | ||

| Explosion-proof rating:Exia IICT4...T6 Ga | ||||

| Temperature range(gas) | Operating temperature Ta | |||

| T4 | -40℃+70℃ | |||

| T5 | -40℃+55℃ | |||

| T6 | -40℃+40℃ | |||

| Storage temperature | -40℃~85℃ | |||

| Relative humidity | (5%~95%)RH | |||

| Explosion proof certification | CVP2000-1 Type:Exia Ⅱ C T4...T6 Ga. | |||

| CVP2000-2 Type:Ex db ⅡC T4...T6 Gb;Exia Ⅱ C T4...T6 Ga;Ex tb ⅢCT80℃..T130℃Db | ||||

| CVP2000-3 Type:Ex db ⅡC T4...T6 Gb;Exia ⅡC T4...T6 Ga;Ex tb ⅢCT80℃...T130℃Db | ||||

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]